.gif)

New Gaylord Box Styles and Features

When you use Gaylord boxes, you are using a common packaging practice and an economical way of shipping materials from point A to point B. Your results are increased efficiency, cleaner material and cost savings. We have several types of new Gaylord boxes in-stock but if you need a custom Gaylord to meet your specific needs, we do that too.

BOX TYPES

RECTANGLE boxes can have full flap tops & bottoms, open tops & full flap bottoms, flange tops & full flap bottoms, or open tops & drop-in bottoms. Rectangles tend to be easier to use and set up because they keep their shape. They are also easier to fill and empty for most users.

OCTAGON boxes can have open tops & full flap bottoms or open tops and drop-in bottoms. Octagon-shaped boxes (or octobins) tend to have higher strength at the corners because the weight is distributed over these extra corners.

TOP & BOTTOM TYPES

OPEN TOP / FULL FLAP BOTTOM is also known as an HSC (half-slotted container) and has one set of flaps on the bottom and none on the top. They require a lid if the box needs to be sealed shut. HSCs can be made from one to eight walls thick and are used in a wide variety of industries when new. Many choose an HSC when using a poly liner or a lid. It’s available in both rectangular and octagonal shapes.

FULL FLAP TOP & BOTTOM is also known as an RSC (regular-slotted container) and has flaps on both the top and bottom. Used RSC boxes are commonly used in the recycling of various commodities and when new, are often used for shipping food ingredients. If you ship valuable products or wish to prevent wandering eyes and sticky hands, consider an RSC. It’s also great for providing protection from damage during shipment. This box is typically rectangular in shape and can be made from one to six walls thick.

DROP IN BOTTOM WITH PAD (aka MODOCT) are typically four- or five-wall boxes that have partial flaps on the bottom that secure the box once it is erected. By having a partial flap on the bottom, these boxes require a separate pad or sheet to cover the area in the center of the box left open by the short flaps. Helluva Container always includes the pads with every used box. These boxes are mostly used in the plastics industry when new. They take up less space in a truck and are more economical than a full-flap bottom box.

LID: Used to seal shut an Open Top / Full Flap Bottom box. Lids are available in both rectangular and octagonal shapes.

FLANGE TOP: A flange is a shorter top flap on a Gaylord box. Flanges aid in extra rigidity for stacking and reducing bulging.

DOMELOCK BOTTOM: are typically three-wall boxes that have interlocking flaps on the bottom that secure the box once it is erected. Watch the How To Setup video or read the How to Setup document.

SLEEVE & TRAY is any box that doesn’t have either top or bottom flaps. This style requires a separate tray for the box to sit into and a tray to cover the top as well. These can be made from one to six walls thick. This type of box is typically only useful for long-term storage or for industries that use them internally and ship them between locations. Otherwise, these are a one-trip, one-use option. Watch the How To Setup video or read the How to Setup document.

FEATURES

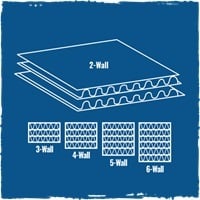

WALLS are made up of linerboard and a medium. Linerboard is the flat material on the outside of and between the medium. The medium are the arches (or flutes) between the liner board and maximize the bending rigidity, act as a cushion, and serve as an insulator. Flutes come in different sizes with larger flutes generally providing greater strength and cushioning. You can determine the number of walls by counting the rows of flutes. Two wall boxes have two rows of flutes, three wall have three, etc. Our used Gaylord boxes range from two to six walls.

HANDLES have your box designed with handles to aid in moving the box around in your warehouse.

ECT stands for Edge Crush Test and tests the amount of force needed to crush the edges and corners of a box. The test shows the resistance in pounds per lineal inch (lb/in) but is expressed as ECT. The higher the ECT number, the more resistant the box is to being crushed. This is a critical factor when designing a new Gaylord box that will be stacked.

Read Our Blog

If your company gets raw material in Gaylord boxes, totes or bins and wants toget paid for your...

We tend to get a lot of questions about Gaylord boxes from people outside the industry. After all,...

It’s a broad question with many answers, but it might just be the most important thing to consider...